A new University of Guelph-designed material for surgical mask filters could offer a more breathable and sustainable alternative to traditional surgical masks.

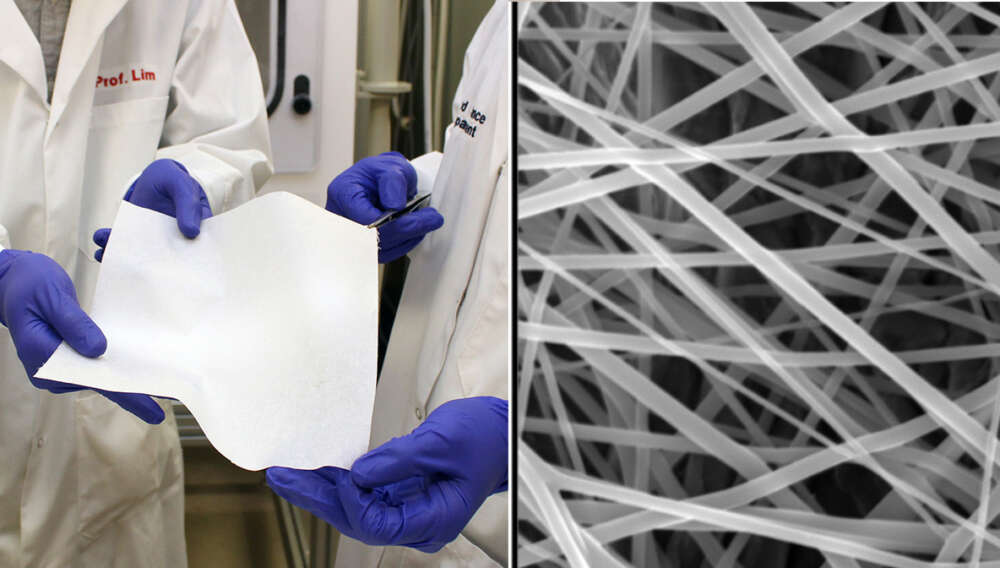

Dr. Loong-Tak Lim, a food science professor in the Ontario Agricultural College, and graduate student Singam Suranjoy Singh have made a non-woven surgical mask filter from plant cellulose. The mask’s biodegradable filter was designed to mitigate the spread of COVID-19.

“The idea behind our new material is to filter and destroy pathogens,” said Lim. “The SARS-CoV-2 virus is very small, so our non-woven mask is designed with smaller fibres to filter better than typical surgical masks.”

The new filter is designed with electrospun fibres produced using electrostatic force. This technology stretches the cellulose strands into a few hundred nanometres, which is two to three orders of magnitude smaller than fibres in conventional surgical masks.

Lim says that non-woven filters with small fibres are more breathable and more efficient at filtering microscopic pathogens like viruses, while traditional mask filters are made of propylene and polyester, which are not biodegradable.

“N-95 mask filters are manufactured using a technology called melt spinning, which produces thicker fibres and a thicker membrane,” he said.

“Compared to N-95 mask filters, electrospun fibres have a lower pressure drop – the difference in pressure between the inside and outside of the mask – which is an indication that it is easier to breathe through.”

Lim says that to further increase the mask’s proficiency, the electrospun filter has been reinforced with silver particles, which have antimicrobial properties.

“As the fibre comes in contact with moisture from breathing, the silver particles release ions that destroy microorganisms,” he said.

The team plans to test the filter’s ability to destroy pathogens in different environments that simulate breathing. They will also investigate ways to integrate their non-woven electrospun filters into commercially available masks.

“The pandemic has changed consumer behaviour and, even after mask mandates lift, people may be more inclined to wear masks during cold and flu season,” said Lim. “With masks becoming a common practice going forward, we want to offer an effective and sustainable option for consumers.”

This project was funded by the University of Guelph’s COVID-19 Research Development and Catalyst Fund and the Department of Food Science. Other collaborators involved with this project are Dr. John Phillips, Dr. Alex zur Linden, Dr. Lawrence Goodridge and Dr. Manickavasagan Annamalai.

Contact

Dr. Loong-Tak Lim

llim@uoguelph.ca